Posted by Mike Cunningham on Feb 4th 2025

Packaging with Tape and Automation

Packaging plays a vital role in today’s fast-paced business landscape, ensuring product protection, preservation, and presentation. As the packaging industry continues to grow and adapt to changing market demands, it is crucial for companies to stay ahead and offer exceptional packaging solutions.

The tape used in packaging is more than just an adhesive, it is a critical component that ensures the security and integrity of the package during transit. Using the right tape prevents boxes from opening unexpectedly, which can lead to product damage, loss, or contamination. Tape is an important aspect of packaging that is still too often overlooked.

Sustainability is becoming increasingly important in packaging decisions. There are several environmentally friendly tape options available. For example, the water-activated tape is made from renewable materials like paper and starch-based adhesives, making it both recyclable and biodegradable. Additionally, there are tapes made from Post-Consumer Recycled (PCR) and Post-Industrial Recycled (PIR) content, tapes that are Cradle to Cradle certified, as well as PE tapes, masking tapes, and flatback tapes – all manufactured with sustainability in mind. There is a lot to choose from.

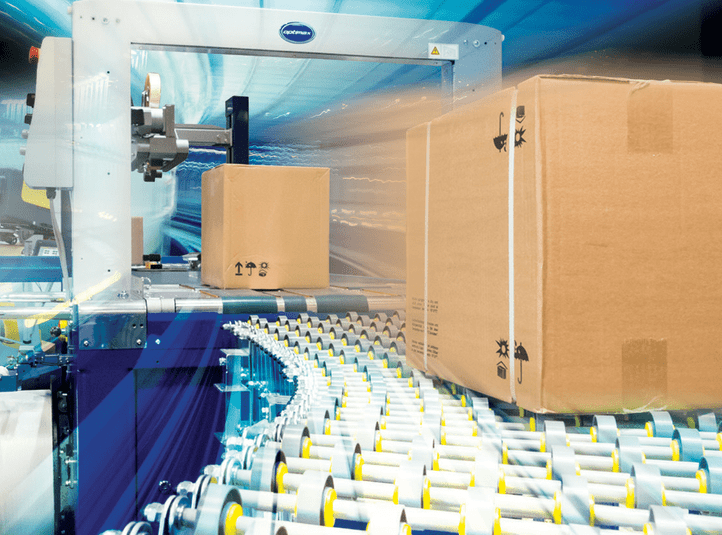

Implementing semi or fully automatic case erectors and sealers can really revolutionize packaging efficiency. Especially in high-volume environments where hundreds or thousands of boxes are packed and shipped daily. These machines automate the process of assembling and sealing boxes, which accelerates workflow, improves consistency and reduces human error. There is a wide variety of equipment available on the market, so it is important to choose the one that best fits your needs. Each machine, each solution, is different.

Get in touch with us today at 813 242 6995 or sales@quickpakinc.com to discuss in more detail and how we can help you automate your packing process.