May 27th 2025

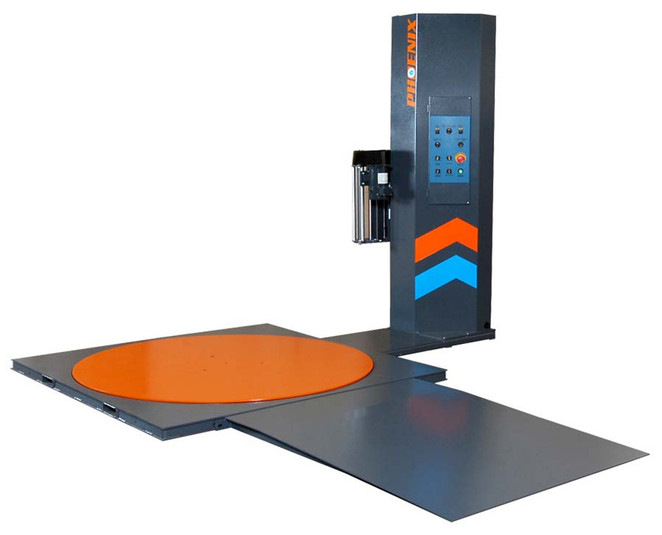

Why You Need a Pallet Stretch Wrapping Machine.

Most shipping departments handle a large volume of different load sizes daily. A small order may head off to one customer, while a much larger batch of products moves out to another plant. As a result, your team is almost always strapping, wrapping, and palletizing loads. You, in turn, are always looking for ways to make operations more efficient. A stretch wrapper could be the solution you’re seeking.

If you haven’t already invested in a stretch wrap turntable, you may want to consider it to speed up operations and save time. The turntable will save you time because it automates some of the tasks your team is completing by hand. Rather than someone grabbing the stretch film and manually wrapping the pallet, the turntable does it automatically.

This reduces the time and effort your team has to put into wrapping each load. It’s more efficient, which means you can move more pallets through more quickly. Your team can get more done in less time, meaning you’ll have the capacity to handle even more orders coming through the shipping department.

Another benefit of the stretch wrap turntable is its ability to make your workplace safer for your employees. Since it automates tasks, it reduces the fatigue your employees may experience when they’re on the floor. If they’re manually wrapping multiple pallets per hour, they’re going to eventually get tired.

Workplace fatigue can have many negative effects, including poor decision making. Employees may act in an unsafe manner. They may also act in unsafe ways if they feel they need to rush. They may be concerned about not meeting quota or having a large and growing number of pallets to wrap.

The wrapping machine doesn’t get tired. As much as it completes wrapping faster, it also doesn’t rush. Additionally, much of the stretch wrap made today requires employees to walk backwards around loads to secure them properly. This is a safety concern in the manufacturing environment. Finally, it also comes with safeguards to protect your employees. You benefit from fewer injuries and safer workers.

An old saying is “time is money,” and those working in a shipping department often feel the truth of these words. If you don’t get an order out on time, the customer may send the order back, ask for a discount, or, even worse, place the next order with the competition.

Inefficiency also decreases productivity. The less productive you are, the more it shows on the bottom line. Inefficiency can also run up your labor costs.

Rushing can also cause problems though, especially if pallets aren’t wrapped correctly. Damages can occur if stretch wrap is applied incorrectly, which then costs the company as well.

A Turntable to Fit Your Needs: Stretch wrappers come in different sizes and models and speeds. Many of them are designed to work with high volumes and different load sizes. Many are also designed to save space, meaning you don’t need to worry about them crowding the floor of your busy shipping department.

If you haven’t thought about a stretch wrap turntable yet, maybe it’s time to consider one for your shipping operation.

Call us at 813 242 6995 or reach out to sales@quickpakinc.com for the perfect wrapper.