Posted by Mike Cunningham on Jan 21st 2025

Time to Automate your Packaging?

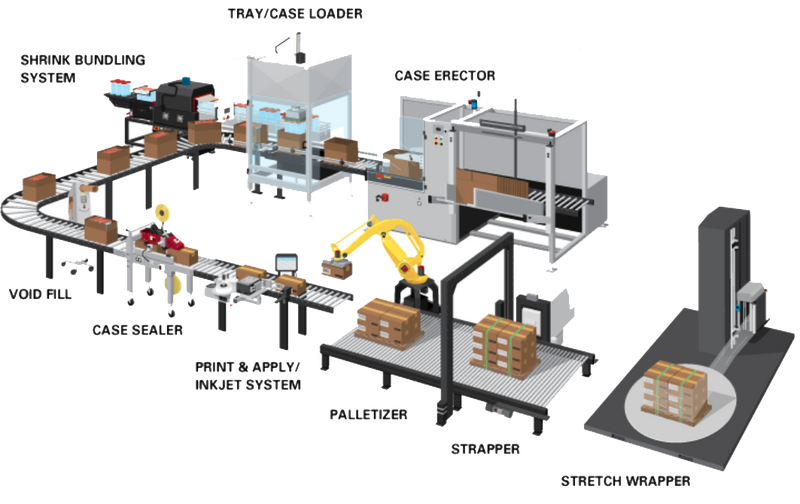

Packaging automation is the process of packaging products without or with less manual human intervention, using machinery to assemble or dispense packaging materials. It can also involve the movement of product throughout a warehouse between picking, packing and dispatch sites.

Labor costs represent a substantial portion of many companies’ operating expenses. The good news is that implementing automated packaging systems can drastically improve your productivity, lower costs in multiple areas and enhance your sustainability without the associated increase in headcount.

Let us look at the benefits packaging automation offers:

Reduced pack times & increased throughput – using packaging machinery can significantly speed up your packing operation. In practice, automated packing systems can double your throughput without the need to increase your headcount.

Fewer manual touch points – implementing packaging automation means you have a reduced requirement for human intervention. You could reallocate resources or use less packers, while productivity increases.

Lower labor costs long-term – the combination of increased productivity but the need for less manual intervention means you can look to lower labor costs long term and may need a reduced headcount. Plus, automation can reduce (or even eliminate) the need for seasonal labor hires during peak periods. Savings can range from 25% to 50% once a piece of machinery has returned on investment.

Enhanced health and safety – automated packaging eliminates the need for your team to perform physically demanding or repetitive tasks, reducing the risk of workplace injuries and associated costs.

Reduced waste & packaging use – employing packaging automation means you can cut the amount of packaging use, and the lack of human error means the right amount of packaging is used every time. This helps you reduce waste and can enable you to lower the cost of your packaging consumables while improving sustainability.

Fewer damage & returns – the consistent packaging provided by automated packing systems ensures your packaging quality is maintained. This will help reduce damage and associated returns – along with the reverse logistics costs.

While labor costs rise, investing in packaging automation can help you mitigate or offset increased financial burdens associated with this area. The wide-ranging benefits of using packaging machinery can also deliver savings in other areas of your supply chain, while future-proofing your packing process against spikes in demand and seasonal peaks.