Posted by Mike Cunningham on May 2nd 2024

Temperature Controlled Packaging

The vital role of temperature indicators in pharmaceutical packaging. For businesses dealing with pharmaceutical and medical products daily, packaging is a huge factor in the success of your operation. In fact, the packaging responsible for protecting and transporting these products is just as important as the manufacturing of the treatment or pharmaceutical device itself.

Throughout the journey from production to consumption, diligence is necessary, especially concerning temperature control. Even the slightest deviation in temperature can compromise medications, rendering them ineffective or, worse, hazardous to patients. Therefore, it becomes crucial to address the challenges posed by the ‘last mile’ of deliveries, where temperature maintenance is critical.

Temperature indicators act as guardians, providing evidence when pharmaceutical products have been exposed to temperatures above or below a chosen threshold.

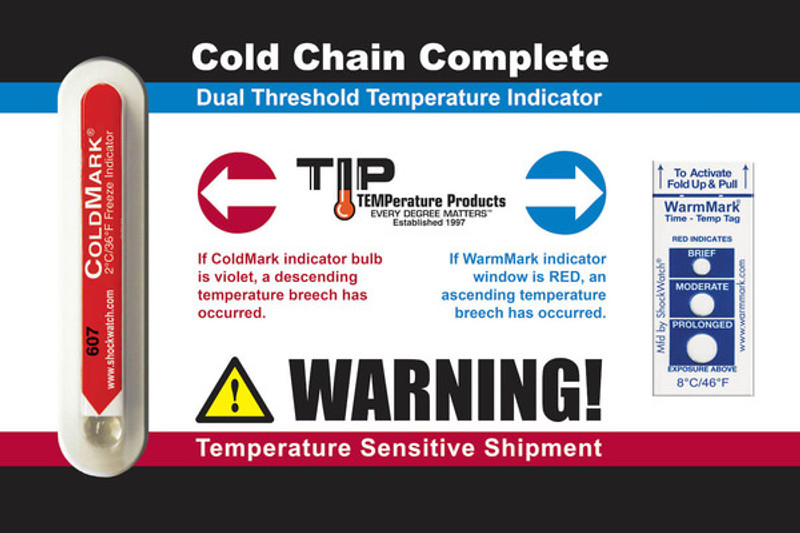

These indicators come in various forms, including labels, tags, and electronic devices, each designed to suit different packaging requirements.

Temperature indicator labels: These are simple, cost-effective solutions that change color or display a message when exposed to temperatures outside of the specified range. They are often attached to individual packages and provide visual cues to indicate whether the product has been subjected to poor conditions.

Electronic data loggers: More advanced temperature indicators, these devices record temperature data over time and can provide detailed reports of temperatures. They are particularly useful for sensitive products that require strict temperature monitoring throughout the supply chain.

However, given their cost, electronic data loggers are typically used per pallet, meaning individual shipments do not benefit from the physical evidence provided by temperature indicator labels.

By incorporating temperature indicators into pharmaceutical packaging, manufacturers and distributors can take proactive measures to safeguard product integrity, protect consumers, and even save on costs.

Quality assurance: Temperature indicators play a crucial role in quality assurance by providing evidence of proper storage conditions throughout the product's journey. This data is invaluable for regulatory compliance and quality control processes.

Supply chain management: In the complex network of pharmaceutical supply chains, temperature indicators help track the environmental conditions to which products are exposed during transportation and storage. This visibility enables timely interventions to prevent temperature-related damage and ensure that medications reach patients in optimal condition.

Cost savings: The use of temperature indicators could reduce wastage rates by up to 30%.

Easy decision-making: Users can quickly tell which products are safe to use, minimizing the risk of unsafe consumption.

Let us talk cold chain call 813 242 6995 or sales@quickpakinc.com