Posted by Mike Cunningham on Feb 19th 2026

Solve Venting Challenges with AirFlow Vented Stretch Film

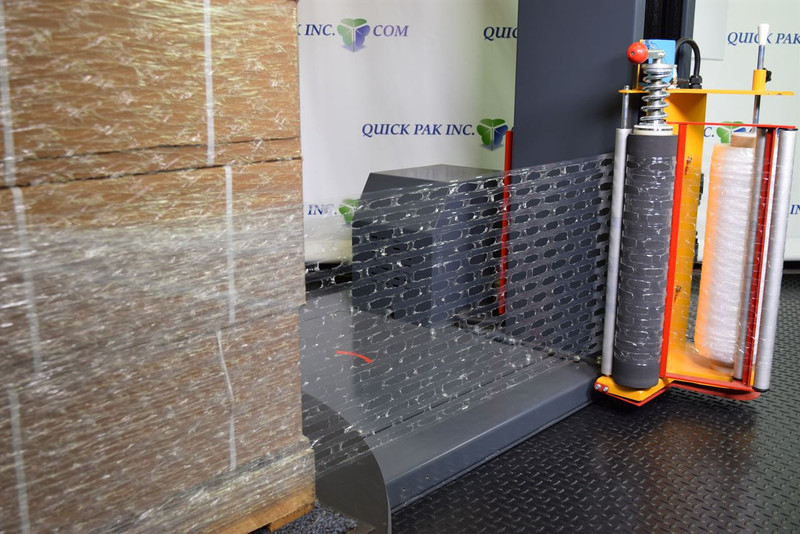

Airflow ensures your products arrive at their destination in pristine condition and without condensation. That’s why we’re proud to introduce our latest innovation of Airflow Reinforced Ventilated Stretch Film. Designed to meet the unique challenges of modern transportation.

Traditional packaging solutions often fall short when it comes to accommodating products that require airflow during transit. Whether it’s soda and beer, dairy products, eggs, or pharmaceuticals, maintaining optimal conditions is essential to preserving freshness, potency, and quality.

Imagine a stretch film that not only secures your cargo but also allows it to breathe, preventing pressure buildup, moisture retention, and bacterial growth. With Airflow pallet wrap, your products stay cool, dry, and protected throughout their journey, eliminating the risk of spoilage, damage, or compromised integrity.

What sets Airflow stretch wrap apart is its superior strength, elasticity, and cost-effectiveness. Our hand-grade and machine-grade options offer unparalleled performance, stretching to 50% and 250%, respectively, while remaining nearly 50% more affordable than alternative vented films.

Airflow Ventilated Stretch Wrap, also known as perforated stretch wrap, is designed to meet the specific needs of palletizing beverages, including beer, soft drinks, and other beverages. With its unique die-cut holes for ventilation, our Airflow ventilated stretch wrap allows for condensation to leave the pallet. This is essential for packaged goods and other packaging materials such as labels and printed display cartons.

Reason to use Airflow Vented Pallet Wrap:

Even Cooling: The die-cut holes allow products to cool evenly and maintain the same temperature throughout the pallet. This not only ensures product quality but also reduces cooling costs by allowing for faster cooling.

Reduce Spoilage: Unlike regular stretch film, ventilated stretch film prevents internal buildup by allowing cool air to enter the pallet and humidity to escape. This reduces the risk of spoilage during storage and transit.

Waste Reduction: Airflow Ventilated Stretch Wrap is 100% recyclable and designed for source reduction. This minimizes environmental impact and landfill space while maintaining product integrity.

Labor Savings: Compatible with conventional stretch wrapper machines, we offer a quick and easy wrapping solution that requires only one person for application. It does not need to be tied off, further streamlining the process.

Forklift Friendly: Perforated stretch film does not tangle in forklift wheels, ensuring smooth operations and reducing the risk of accidents. Its sticky properties keep it wadded into a ball and out of the forklift’s wheels, saving time and maintenance costs.

Less Wear: Unlike netting, Airflow ventilated stretch film dispenses freely without fraying or tangling in the wrapper’s rollers, minimizing downtime and maintenance.

Freezer Friendly: With its chemical composition, ventilated stretch film does not have a flash freeze breaking point, making it suitable for all cold storage and freezing applications.

See what Airflow Vented Stretch Films can do for you, reach out to us at 813 242 6995 or email sales@quickpakinc.com