Posted by Mike Cunningham on Sep 15th 2025

Rotating Stretch Film Stock

Stretch film is essential to transporting and storing goods safely. It keeps items from moving during transit, while protecting products from both indoor and outdoor elements. Due to the product’s importance, companies need to understand how to prevent and detect stretch film expiration. The various film types react differently to extreme heat, cold, humidity, and other factors.

Stretch film lasts for a long time, but extreme temperatures can impact performance:

Heat: High heat affects film by making it more extensible so that the wrap no longer maintains its width and will stretch more than desired.

Cold: The opposite is true with freezing temperatures. Cold exposure results in film that no longer stretches as expected, reducing the yield and tackifier.

Films will react differently depending on their type. For instance, blown and cast films can undergo a process known as telescoping when exposed to high heat. The layers slip and create a roll edge that is no longer straight, leading to issues when wrapping products. The challenge with telescoping is that it’s difficult to detect until the wrap is unraveled, meaning prevention is key. Blown film is instead better suited to colder conditions, as its high opacity makes it more resistant to temperature changes.

Temperature is not the only factor in stretch film expiration. Humidity also impacts film due to its cardboard core. The higher the humidity, the greater the likelihood of the core squeezing or crushing. The result can be a complete product failure or an inability for the core to fit onto a wrapping machine.

Another side effect of humidity occurs when the product itself is the source of the humidity and higher temperature. Most stretch films act as insulators, meaning when products are wrapped, there is nowhere for air to go. This is a good thing for most products as it reduces exposure to oxygen. However, wrapping a product when it is still warm may lead to condensation. Vented film allows air to pass through the film, creating a pathway for moisture to escape that would otherwise be trapped and damage the box or any tape adhesive.

Film has a long shelf life, but some factors affect the lifespan and appearance inherent to the film itself. For instance, pre-stretched film can have a shorter lifespan due to its manufacturing method. Air entrapped in the process of the film being stretched is eliminated over time as its core collapses, making the roll tighter and reducing the pre-stretched film’s effectiveness.

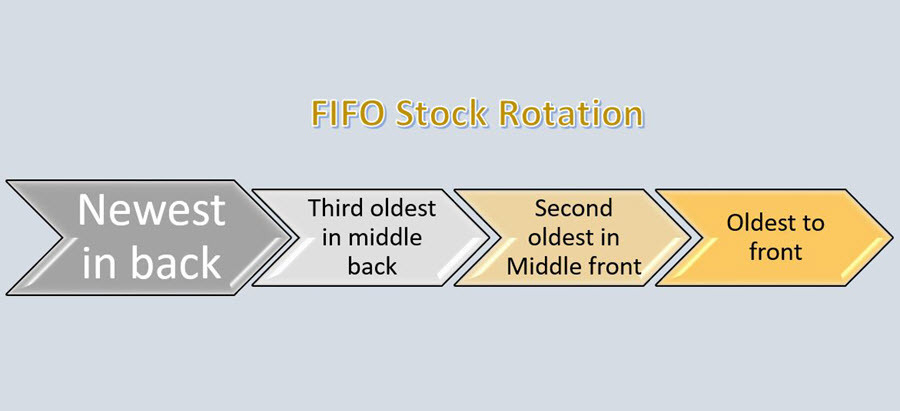

As temperatures and other conditions often change throughout the year, predicting which film is best for all-around performance becomes difficult. The best way to manage stretch film expiration is to employ the (first in, first out) concept for rotating stock. This ensures inventory is used in order of age. For more information on stretch films call us at 813 242 6995 or reach out to sales@quickpakinc.com