Posted by Mike Cunningham on Feb 11th 2025

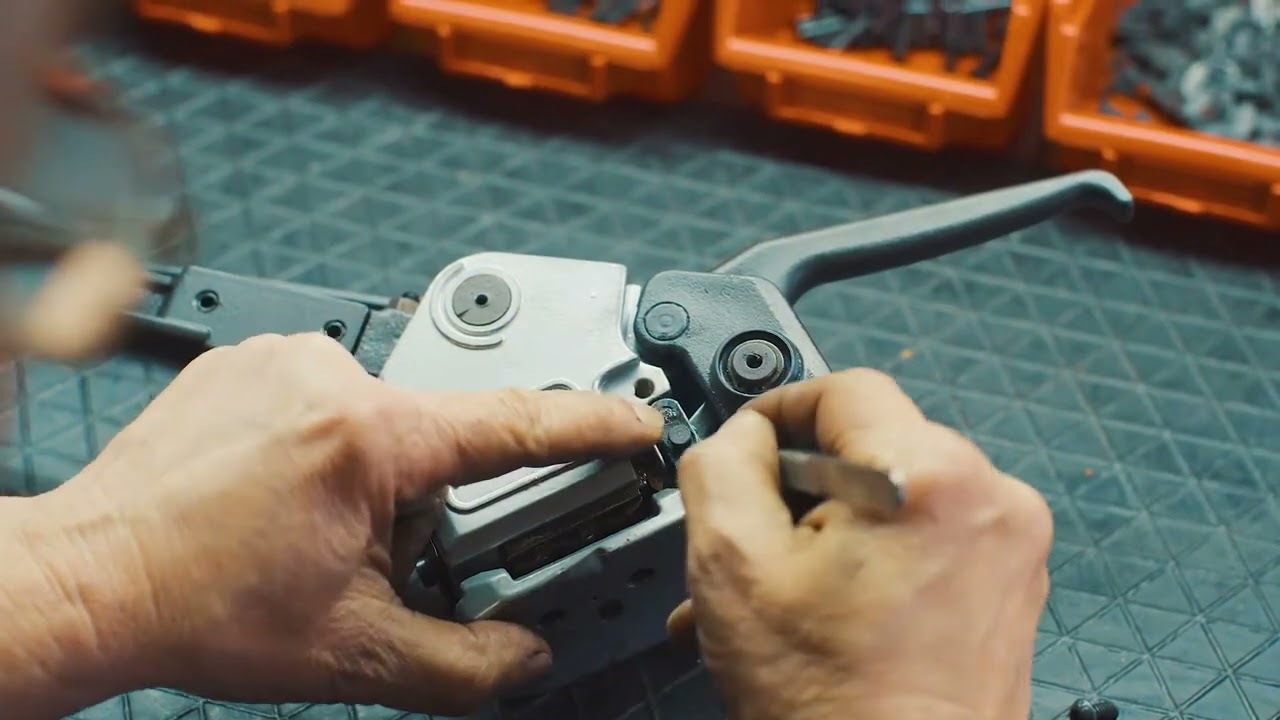

Preventive Maintenance for Strapping Tools

Many people live “if it ain’t broke, don’t fix it.” Often, they misinterpret this to mean that you should wait until a machine or strapping tool breaks to do any maintenance on it. While you cannot always prevent repairs, you can usually avoid major breakdowns and lost productivity by doing just a little preventive maintenance. Here is how taking a few small steps to maintain your strapping tools can save you both time and money.

Every machine will eventually need maintenance and repair. For strapping tools in your workplace, tensioners, cutters, and sealers may need attention. Important parts such as motor bearings might need to be replaced after so many cycles from wear and tear.

Wear and tear are unavoidable, but it does not mean you have to wait for the tool to stop working before running maintenance. In fact, replacing parts and cleaning the tool on a regular basis help keep it in good order.

Preventive maintenance helps you avoid major breakdowns, where the tool stops working altogether and it may be days before you get it working again. Those breakdowns cost your team because they mean more downtime. Downtime is lost productivity, which impacts on your business’s bottom line.

Preventive Maintenance Extends Tool Life: The other major reason preventive maintenance for a strapping tool is so important is that it can extend the life of your equipment.

A poorly maintained tool may break down more often, sometimes in such a way that makes it too expensive to fix. You might find you are replacing tools every two years, instead of every five or so.

A good maintenance plan extends the life of the tool by keeping it in good working order longer. Strapping tools are no small investment for most plants, so protect your investment with regular maintenance.

Good Maintenance Means Better Tool Performance: A dirty strapping tool or dull cutters can spell trouble for your strapping team. The tool may not function as well as it should, which could lead to poor strapping jobs. Your team might end up strapping the same shipment two or three times before it is done right. That wastes time and money and reduces your productivity. This also leads to more wasted materials, which run up your costs.

When your strapping tools are kept clean and working properly, your team will be able to get the strapping done right the first time.

Well-Maintained Tools Are Safer: Another way of strapping tool maintenance saves you time and money is by reducing the potential for injury.

A poorly maintained strapping tool is simply not as safe, leading to increased risk of injury. For example, dull blades might encourage employees to put their fingers nearer to sharp parts, twist, or pry tools, or try and remove jams.

Finally, the poorly maintained strapping tool does not perform as well. This means your team must work harder. They might have to reapply strapping to the same shipment or use more force to apply a seal or tension the strap properly. This leads to heightened fatigue, job satisfaction and increases the risk of injury on the floor.

Invest in a Preventive Maintenance Program: As you can see, keeping your strapping tools in good order is key to safety, productivity, and cost-savings. Invest in your maintenance and see the difference it makes for your plant.

Call Quick Pak Inc service dept at 813 242 6995 or reach out to sales@quickpakinc.com