Posted by Mike Cunningham on Aug 7th 2025

Pallet Wrapper Preventative Maintenance Tips

Revolution Stretch Wrappers are incredibly user-friendly but there will be times you will appreciate or need the assistance of a highly qualified technician to keep your lines running efficiently. Always a great idea to have some preventative maintenance done, this keep the wrapper running and avoids unnecessary down time.

Quick Pak’s Equipment Repair Services ensures that every piece of your end-of-line packaging equipment operates at its best. We specialize in repairing all makes and models of packaging equipment, providing a full suite of services to cater to your unique needs.

Few Tips to Keep your pallet wrapper running great.

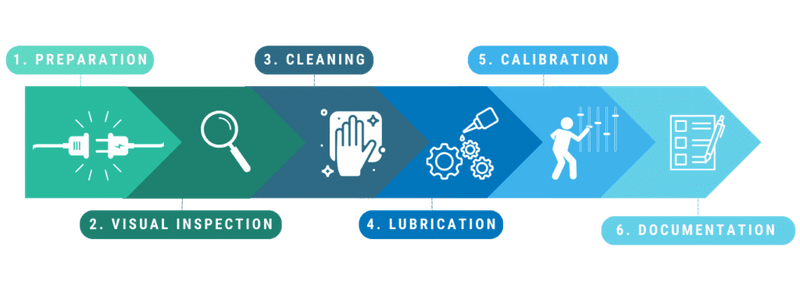

General Pallet Wrapper Maintenance: First thing’s first. Unplug the machine from the power outlet and clean out any debris around and under the pallet wrapping machine. Over time, pieces of stretch film, chips of wood from pallets, and trash will eventually find their way in and underneath the machine. Loose material and mechanical moving parts do not mix very well.

Perform a Visual Inspection: Once you’ve cleaned up any loose debris, perform a visual inspection of the machine. Are there any obvious signs of damage to the mechanical parts or cabling? If so, tag it and call our service dept immediately. Look at the rollers and other moving parts. Strands of stretch film waste can get wrapped around them and cause the bearing and machine to strain under operation. This can lead to blown fuses and a shortened motor life.

Inspect and Clean the Sensors or Photocells: Dirty photocells and sensors can lead to improperly wrapped loads that can damage products or create spills during transport. Depending on your specific pallet wrapping model, the sensors may be located in an out-of-the-way place. Take a damp cloth, gently wipe it down, and remove any dirt buildup.

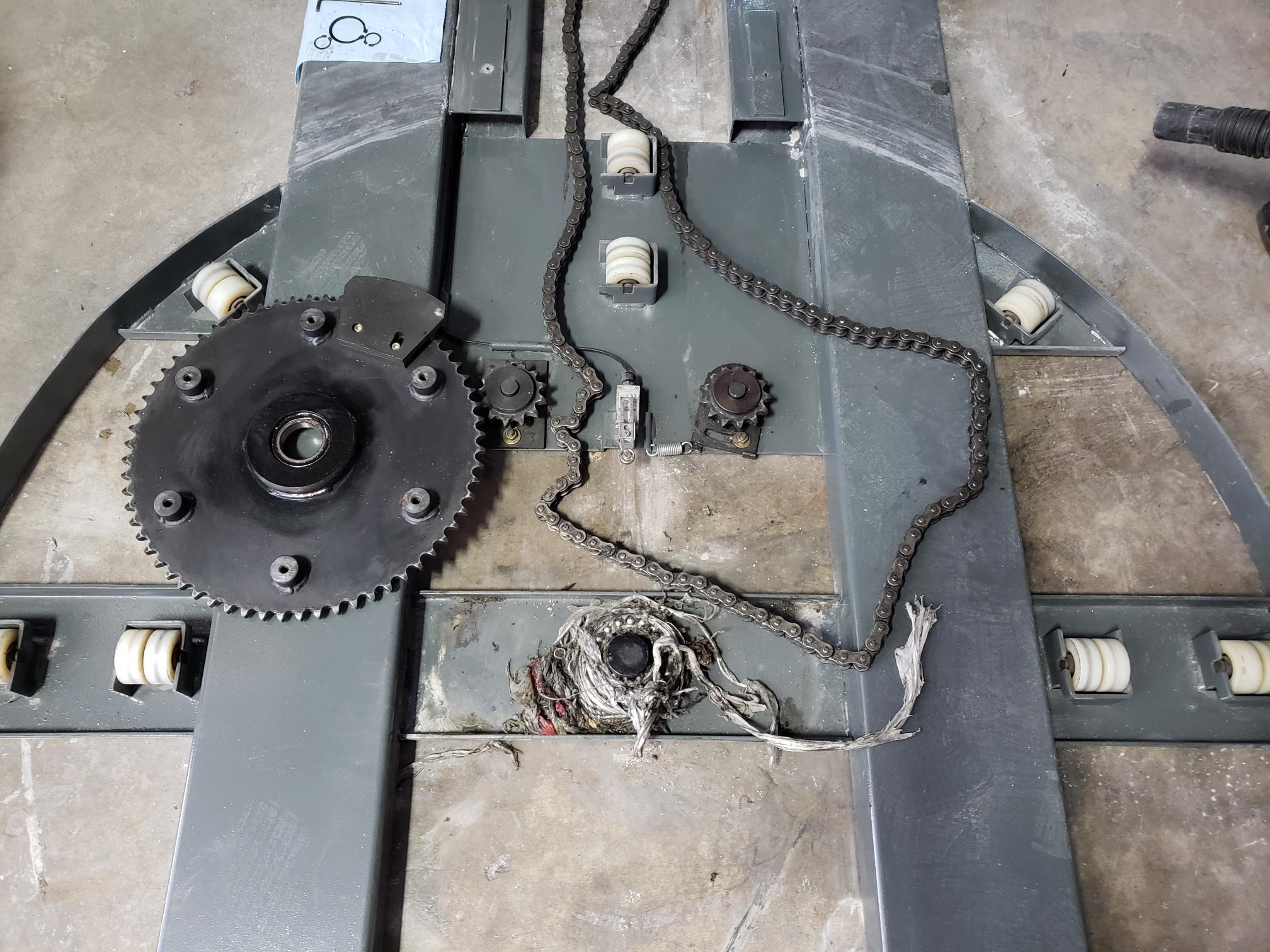

Drive Maintenance: The drive system on your stretch wrapper could utilize belts, chains, or a combination of the two. Refer to the user manual and use the proper lubricant to ensure smooth and reliable operation. Avoid over lubricating as it can cause splattering, fouling, and dirt accumulation in other areas over time.

This is a good time to inspect the chain or belt for tension and wear. If you notice signs of degradation, immediately tag the machine and order a replacement part. Any damage can result in expensive repairs.

Lubrication: Generally speaking, most pallet wrapping machines have two different lubrication points. Refer to your owner’s manual for the exact location(s) and approved lubricant.

Avoid using non-recommended products as they may not have the correct formulation to ensure consistent performance and long life. Try to avoid over-lubricating as it can cause the grease to splatter and accumulate on other parts.

If you need equipment service or parts for your stretch wrapper call Quick Pak Inc @ 813 242 6995 or reach out to sales@quickpakinc.com