Feb 17th 2025

Packaging Automation from Entry, Mid and Top-level.

Entry-level packaging automation solutions. Packaging machinery does not have to break the bank. Small solutions can offer a big impact. Some examples of entry-level automation include:

Gummed Paper Tape Machines: These compact but efficient electronic tape dispensers will moisten and dispense lengths of gummed paper tape at the touch of a button. Available in a range of models, they can be bought for less than $1,000 and can help improve packs and cut the amount of tape you need to use.

Friction Weld Strapping Tools: If you are strapping pallets by hand using polypropylene or polyester strapping, a friction welder could make your life easier. These battery-operated handheld devices will tension, cut, and seal strapping for you at the touch of a button.

Semi-Automatic Stretch Wrappers: Pallet wrappers can seem like big pieces of equipment, but if you are wrapping fifteen or more pallets a day, installing a semi-automatic turntable pallet wrapper, like the Revolution ST, can help you wrap more pallets with less film.

Void Fill Machines: Whether you prefer paper void fill or air bags, individual void fill machines on a packing bench can be used to create protective packing material on-demand, saving time and money.

Mid-Level Packaging Automation Solutions. If you are already using some smaller automated systems listed above and you need another productivity boost, you could also consider these mid-level packaging automation solutions:

Case Erectors: Perfect if you are using a significant number of boxes, case erectors will take a pre-formed case or box, and pop it open and seal the bottom flaps, ready for packing. This speeds up the packing process and helps with uniform package cubage, which will help reduce damage, improve pallet stacking and can even contribute to lower transport costs. Operations from just 2-3 packers can benefit from this type of automation.

Case Sealers: Standalone case sealers will seal boxes using tape or glue. They can be used alone or alongside case erectors. Models are available for mid-range all the way up to high-demand solutions. They can help you accurately control tape usage and cut waste.

Integrated Void Fill Systems: If you’re operating a multi-bench packing area, having void fill on demand at each bench can be important to ensure your products are protected. Many systems can be mounted to fill hoppers or multiple workstations, replenishing air bags or paper cushioning automatically.

Vertical Auto Bagging Machines: This type of bagging machine allows you to insert products and then seal and often label or print them all in one go. There are systems available that can enable you to produce fifty packs per minute. Applications include ecommerce and mail order fulfilment, hardware, automotive and appliance parts, plumbing and heating parts, medical devices and many more.

Strapping Machines: If you are bundling products, securing boxes or even strapping pallets, strapping machines can help you apply, tension, cut and seal strapping with ease.

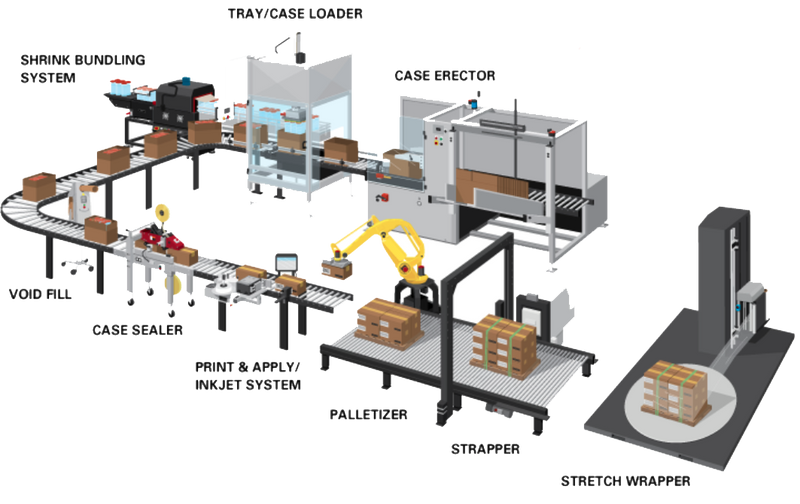

Top Level Packaging Automation Solutions. For even the most demanding operations, there are a huge range of packaging automation solutions available. Key types of top-level automation systems include:

Right Size Carton Systems & Void Reduction Systems: Combining speed with the ability to create the right size box for your products, these machines ensure you are using the ideal size packaging every time. They enable you to maximize cubage and reduce the void in a carton, so you’re not paying to ship empty space. Right size carton systems work by taking blank cardboard and forming it around your products. They can be combined with void fill dispensing and will also seal a lid onto your carton.

Automatic Random Case Sealers: The high-end of the case sealer machine market, random case sealers will seal a range of boxes, rather than just one standard size.

Horizontal Auto Bagging: Enabling you to bag products in-line, horizontal bagging machines will create bags by sealing film while product or boxes flow through them, sealing them inside. They can print and label bags too, ready for shipping.

Conveyors & Labelling: In addition to key packing processes like boxing, sealing, stretch wrapping and bagging, all movement in your operation can be automated with conveyors. Auxiliary actions like labelling or document insertion can also be automated, minimizing manual touch points, so your operation runs fluidly from start to finish.

At Quick Pak Inc we have dedicated experts who can help you start your packaging automation journey. From consulting on the right solutions, supplying the packaging machinery and materials through to demonstrating return on investment. Call us @ 813 242 6996.