Posted by Mike Cunningham on Jun 19th 2025

How Better Packaging Can Slash Costs and Cut Waste

Although packaging helps to protect products during storage and transportation, a poorly optimized operation can hide up to 90% of your packaging costs. By adopting a smarter packaging strategy, your business can cut costs and waste.

Many businesses underestimate the impact of inefficient packaging on their operations. Oversized boxes and excessive void-fill materials can lead to higher costs, increased shipping fees and unnecessary waste.

Customers are becoming increasingly aware of environmental issues and quickly call out businesses that use excessive materials. Addressing these inefficiencies is not just an operational necessity but also a competitive advantage.

Your consumers are also affected by inefficient packaging due to the increased risk of product damage during transit. This can lead to higher return rates, additional costs for the business and a negative experience for your customer.

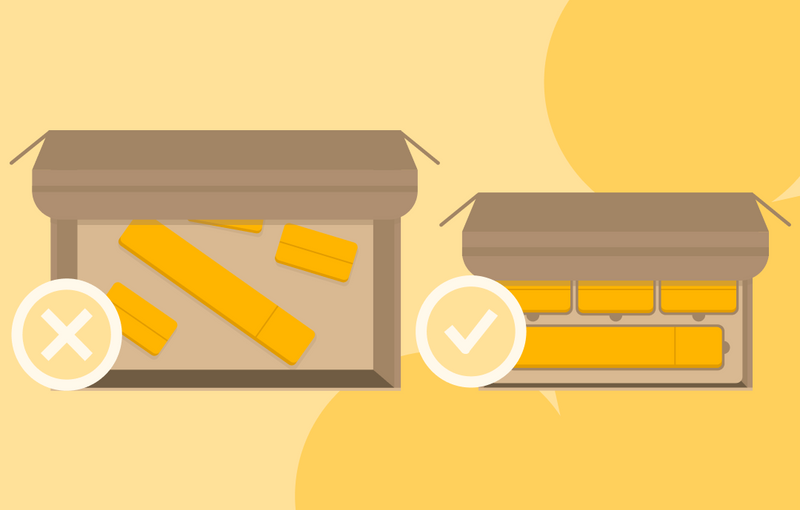

Revaluate your packaging sizes: Take time to consider the products you offer and what packaging solution would work best. Reflect on the process of packing your biggest items vs. your smallest, and how much extra space are you accommodating?

The packaging material you’re currently using isn’t the best fit for your business, or you need to condense/increase sizes. By eliminating excess space, you can reduce material and shipping costs while enhancing overall product protection.

Switching to more sustainable materials: Prioritizing environmentally friendly solutions can often help you cut down waste and minimize transportation costs.

Make your packaging lighter: Reducing the weight of packaging materials without compromising strength is another effective strategy. Lighter, more space-efficient packaging can reduce your transport costs. Finding the perfect balance of product protection can be difficult, but having a space-efficient pack can offer a better fit for the product (so you’re not shipping air) and allow for pallet optimization.

Reclaim warehouse space: An often-overlooked area of operation is your valuable warehouse space. Bulky or inefficient packaging can take up unnecessary room, increasing storage costs and limiting operational capacity.

By maximizing storage efficiency or adopting a Just in Time strategy, you can free up significant space in your facility. Not only does this save on storage costs, but you’ll also reduce wastage in your supply chain, making it more sustainable.

Use packaging optimization to scale your business: Consider how your operation dealt with varying environments, such as increased demand in 2024; it may be time to consider introducing automation.

In larger or growing operations, efficiency, sustainability, and cost management are always important. By utilizing packaging automation, businesses can reduce waste and achieve significant savings while improving throughput and reliability. Investing in optimization also helps businesses stay competitive by reducing downtime and ensuring consistent quality across high-volume outputs.

While the initial financial investment in packaging machinery may seem daunting, it can provide a return rapidly. Plus, at Quick Pak Inc we offer different finance options to manage costs.